Roller chains facilitate power transmission between machineries in most manufacturing industries. They are mostly found in agricultural machines, heavy duty machines, domestic machines, and many more

Besides, they reduce friction between machine parts hence saving cost on damages and repair.

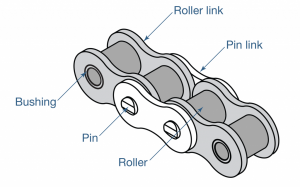

Parts of a roller chain

Bushing: holds the inner plate of roller chains together hence connecting pins to the outer and inner plates and helping to reduce damage on sprocket teeth and around their pins

Pins: are responsible for connecting all parts of the roller chain together firmly

Rollers: allows chain to move freely during work process and cause a reduction in friction

Side Plates: they bear the tension across the chain links, and enable the inner and outer links to transfer the tensile load from pin to pin.

They are mostly found in run conveyors, power machinery, industrial and agricultural machines, wire and tube drawing machines, printing press, cars, motor bicycles, bicycles and for domestic purposes.

They can be found in agricultural machines, industrial machines and for heavy duty purposes. They are mostly used in paper mill equipment, trenches, planters, elevators and lumber mill.

They are mainly used in mining, agriculture and heavy-duty machines

They are one of the widely used roller chains because of their corrosion resistant properties as well as the wide range of temperatures and applications they can work within. They also come in the form of a single, duplex and triple stand roller bearing.

Parts of a stainless-steel roller chain

Pin Link: it forms the outer part of the chain

Roller Link: it comprises of two bushings, two rollers and two inside side plates that are designed to hold everything together

Roller Chain connecting links join two ends of a chain together and come in two configurations which is dependent on their application

Roller chain offset link

Offset links are used to add a “half link” to a strand of roller chain. Any strand of roller chain without the use of an offset will only have an even number of links. This links is primarily used on drives that have shorter lengths of chain where tensioners or adjusters are not used.

How to protect roller chains for effect work and long-lasting effect

Lubrication: Lubricating roller chain and its completing tools makes them last longer and work effectively hence reducing chances of getting damaged early.

Keeping them away from dirt and friction will also make them last longer but in instances where their chains need to be fixed at such dirty places to facilitate work process, it is important that they are cleaned and greased often for them to last a bit longer and run smoothly.