A power transmission system basically aids in transferring mechanical energy in physical motion from one machine to the other without a change in form or nature of components involved. Technically, most machines need some form of mechanical power transmission be it in direct contact or done intermedial.

Here, a mechanical power transmission system involves the transfer of energy from a moving component to the receiving component

Almost all machines have some form of power and motion transmission from an input source. This is usually an electric motor or an internal combustion engine which typically provides rotating driving force via an input shaft–coupling combination.

The purpose of power transmissions

There are many ways to generate power but sometimes it is not possible to generate power where it’s needed or in the right form, direction, or magnitude. Hence electrical & mechanical power transmissions are vital for any engineering product design. Mechanical power transmission and its elements are used for the following reasons;

- Generated power or energy can be converted into a useful form

- Physical constraints limit the power generation at the place where it is used hence it can be transferred from source to a place where it is needed

- It can be used to change direction and magnitude such as speed or torque

- It can be used to change the type of energy i.e., rotational to linear and vice versa

Mechanical power transmission elements

In an engineering product design such as automation drives, machinery, etc., power transmission and its elements make it possible to match the power source to its operating environment and condition of the working elements.

Benefits of power transmission elements

- Transmit power efficiently

- The elements help to split and distribute the power source to run several mechanisms such as a single motor running multiple conveyor belts.

- To change rotational speeds

- Reverse the rotational direction from the motor

- Converts rotational movement into linear reciprocating motion

Types of Mechanical power transmission elements

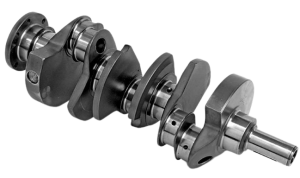

Shafts and couplings are an integral part of the power transmission for modern age engineering product designs such as machinery. Since power transmission shafts are widely used in almost all types of mechanical equipment design, the design is critical for the safe and long life of the machines.

1a. Shafts

A mechanical shaft is a mechanical power transmission element that conveys power and rotational motion from one device to another.

Sub-components such as couplings, gears, pulleys, sprockets, etc. are mounted onto a shaft to transmit power or rotation via the central portion of the component called hub along with retention devices such as keys and splines. The connection should ensure the connection transmits the load, power & rotation without slipping and within the accuracy requirement of the design.

Types of connections and components required to be used along the shaft axis are dictated by the functional requirements of the product and depend on the following factors

– Magnitude of Torque

– Shaft size

– Rotation speed

– Direction of rotation

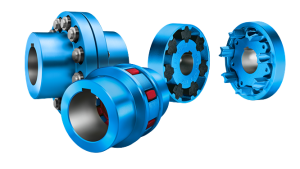

1b. Couplings

Couplings also known as shaft couplings are used to connect two shaft ends together to transmit both angular rotation. The main design requirement for couplings and their retention devices is that the rated torque must be transmitted without slip, premature failure or in some cases it needs to withstand misalignment.

Mechanical power transmission couplings are typically divided into two broad categories

- Rigid coupling

- Flexible coupling

Rigid couplings are simple, easy to design, and comparatively cheap though require precise alignment of the shafts, whereas the flexible couplings can accommodate shaft misalignment.

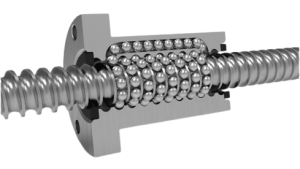

2. Power Screws

A Power screw also known as Leadscrew (or lead screw) and translation screw, is a screw used as a power transmission linkage element in an engineering product such as a machine to translate rotational motion into linear motion. T

Power screws have many applications such as linear leadscrews, machine slides, vices, screw jack, mechanical press steering mechanisms, etc. Most common arrangements are set up such that the power screw rotates and the nut translates into linear motion along with the screws.

These are not used on high power transmission because of large frictional energy losses on screw threads but used on low power intermittent transmission such as low accuracy positioners.

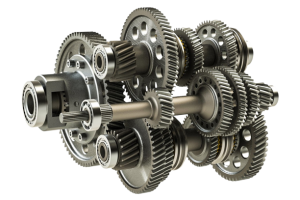

3. Gears and gear trains

Gear trains are multiple sets of gears that transmit power. A gear train is a mechanical power transmission system where gears are installed on shafts so the teeth of the mating gears engage and each roll on each other on its pitch circle diameter.

4. Brakes and Clutches

The main function of a clutch is to bring both elements to a common angular velocity.

The main function of a clutch is to bring both elements to a common angular velocity.

A brake functions in a similar manner, except that one of the elements, is fixed, so when actuated the common angular velocity is zero.

Although brakes and clutches are known for their automotive application, it’s also widely used in winches, mowers, hoists, washing machines, tractors, mills, elevators and excavators.

5. Clutches

Mechanical clutches can be classified and distinguished in a variety of ways depending on their engagement type, operating principle, type of actuation & method of operation.

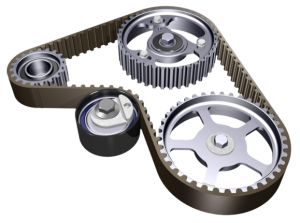

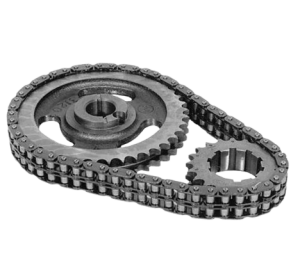

6. Belts, Ropes & Pulleys

Belts and pulleys are used when the distance between the shafts is too far apart to use gears.

Chains are used for lower speed applications where the distance between the shafts is too far apart to use. Here, gear trains and belts are going to support the torque that needs transmitting. They are also a good way of transmitting power when exact speed ratios are needed

COMMON APPLICATIONS OF POWER TRANSMISSIONS

- Water pumps

- Turbines

- Automobiles